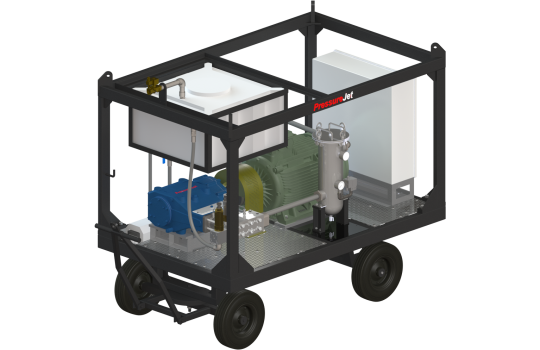

Get Maximum Efficiency with PressureJet Tank and Reactor Cleaning Systems

PressureJet Tank and Reactor Cleaning Systems are engineered to maintain internal vessel surfaces in optimal condition, ensuring maximum heat transfer efficiency, reduced downtime, and improved product quality. In chemical, petrochemical, brewery, and other process industries, contamination buildup on reactor walls, agitator blades, and vessel jackets can severely reduce efficiency, increase reaction times, and decrease yield by up to 15%. Over time, fouled jackets and tanks can increase maintenance costs and shorten equipment lifespan.

Using high-pressure hydro blasting equipment, PressureJet tank and reactor cleaning systems remove contaminants, debris, and fouling efficiently, preventing downstream contamination and ensuring faster batch runs. Clean vessels lead to lower operating costs, improved production efficiency, and better overall plant profitability.

Upgrade to PressureJet Tank and Reactor Cleaning Systems

Ensure cleaner vessels, faster batch runs, lower operating costs, and higher production efficiency with our high-performance, industrial-grade tank and reactor cleaning solutions.

Application of Tank and Reactor Cleaning System

PressureJet tank and reactor cleaning systems are used across industries for a variety of cleaning tasks:

- Chemical and PetroChemical Plants: Reactor vessel cleaning, internal jackets, and pipeline pre-cleaning.

- Breweries & Food Processing Units: Tanks, fermentation vessels, and storage silos cleaning.

- Water Treatment & Storage: Water tank cleaning and maintenance of potable water systems.

- Marine & Ship Industry: Ship tank cleaning, fuel tanks, and ballast tanks.

- Industrial Storage & Silos: Grain, powder, and bulk storage tank cleaning.

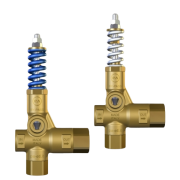

- Ensures accurate pressure regulation for safe pump operation.

- Built with rugged design for long-lasting durability.

- Easy to install and low-maintenance accessory.

- Ideal for High Pressure Industry.

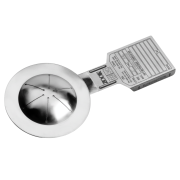

- Rupture disk provides instant pressure relief to protect pumps and operators from overpressure.

- Designed for precise burst pressure ratings to safeguard ultra-high pressure systems.

- Compact design allows easy integration into high-pressure jetting systems.

- Essential safety device for hydro blasting, heat exchanger & industrial cleaning systems.

- Designed for pressures up to 280 BAR with flow capacity up to 80 LPM.

- Optimized internal passages that guarantee reduced pressure loss.

- O-rings of the fittings positioned upstream to the thread : no risk of fittings ejected in case of overpressure.

- Version with knob fitted with locknut for minimum working pressure adjustment.

- Head rotation provides complete internal coverage while speed control delivers optimum jet dwell time

- Easily re-jet the Gopher for more pulling force or forward hitting power depending on the needs of the job

- External port plug allows for fluid refill without tool disassembly

- Polisher, Unplugger, and Universal heads available

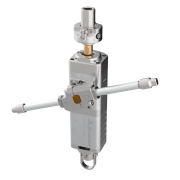

- Self-propelled rotary tank cleaner providing full 360° cleaning coverage.

- Built from acid-resistant stainless steel suitable for HF and HNO? cleaning.

- Operates on hydraulic water jet propulsion — no external power needed.

- Ideal for chemical reactors, tanks, and process vessel cleaning.