Quality Approach

PressureJet has invested over INR 10 Million in establishing a state-of-the-art Quality Department. The facility features 7 SCADA-based computerized test benches, capable of simultaneously managing, monitoring, and controlling the testing of pumps across the power range of: 30 HP to 330 HP

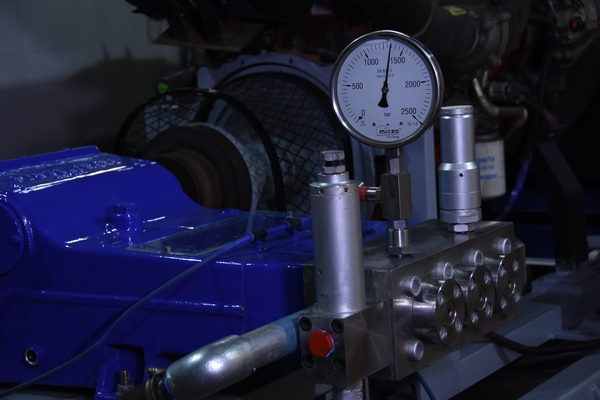

Each test bench is equipped with:

- High-accuracy flow and pressure measurement devices from Siemens and E+H

- Grundfos suction booster pumps

- Temperature sensors, vibration and noise meters

- Pneumatically controlled pressure regulating valve

This ensures every pump is tested against 694 critical quality parameters before dispatch, guaranteeing precise performance and reliability.

From raw material procurement to final inspection, PressureJet employs 257 advanced quality checking instruments — the largest number among high-pressure plunger pump manufacturers in India. Our quality approach includes:

- Testing against 694 quality parameters, covering every critical aspect of pump performance, reliability, and safety

- Controlled environment testing for all precision-engineered components

- Long-duration trials, running from 50 to 500 hours at full load, supported by a captive recirculating cooling system and 100,000-liter underground clean water tank

- Coordinate Measurement Machine (CMM) for GD&T inspections in microns, ensuring the highest precision for the most critical parts

- Real-time online access for clients to monitor pump performance during testing

PressureJet leverages the latest technology to deliver pumps that perform reliably under extreme conditions:

- High-precision flow and pressure measurement devices

- Temperature, vibration, and noise monitoring

- Pneumatically controlled pressure regulation

- SCADA-based process automation for simultaneous multi-pump testing

- CMM inspections in microns for world-class precision on critical components

This ensures that every pump meets the highest global standards, leaving no detail unchecked.

By integrating discipline, innovation, and relentless attention to quality, PressureJet ensures that each pump delivers:

- Consistent performance at rated parameters

- Reliability verified against 694 quality parameters

- Parts precision verified in microns via CMM inspections

- Longevity under continuous and heavy-duty operation

- Peace of mind for clients investing in critical industrial applications

Every pump, every system, every time. That’s the PressureJet promise. With our unmatched quality infrastructure, advanced instruments, and rigorous testing protocols covering 694 quality parameters, and micron-level precision validation via CMM, we deliver world-class pumps engineered for reliability, efficiency, and long-term performance.