1st Choice of Hydro Jetting Contractors

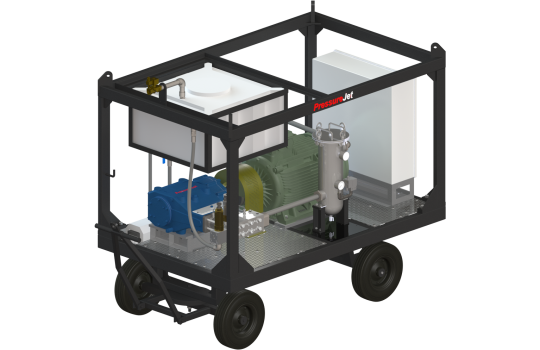

Experience unmatched performance with PressureJet Hydro Jetting Machine, engineered to handle the toughest heat exchanger tube and pipe cleaning applications with pressure up to 1400 Bar and power up to 150 HP. Our advanced hydro jetting solutions harness the power of high pressure water jet cleaning to deliver superior results across industries engaged in heat exchanger, evaporator, and pipeline cleaning.

At PressureJet, we combine efficiency, safety, and reliability with proven performance. Trusted by customers in 50+ countries, PressureJet is globally recognized as a leading manufacturer of high pressure water jetting machines. Each pump system is precision-engineered and manufactured with high-quality standards, backed by expert technical support to ensure maximum uptime, extended service life, and optimized productivity.

Upgrade your operations with PressureJet High Pressure Water Jet Cleaning Technology – available as a compact hydro jetting machine or a heavy-duty industrial hydro jetting system, built for precision, performance and durability.

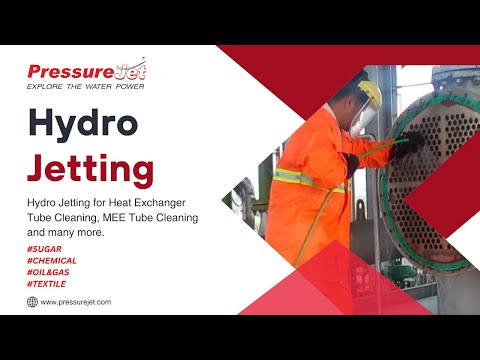

Applications of Hydro Jetting Machines

PressureJet high pressure hydro jetting machines are trusted across industries for a wide range of industrial cleaning applications, including:

- Heat Exchanger Tube Cleaning

- Evaporator Tube Cleaning

- Condenser Tube Cleaning

- Multi Effect Evaporator (MEE) Tube Cleaning

- Falling Film Evaporator (FFE) Tube Cleaning

- Shell and Tube Type Heat Exchanger Tube Cleaning

- Industrial Pipe Cleaning

Industries Using Hydro Jetting Machines

PressureJet high pressure pump systems are widely used by:

- Sugar Mills – for evaporator and juice heater cleaning during maintenance shutdowns.

- Chemical & Petrochemical Plants – for condenser, reboiler, MEE, and heat exchanger tube descaling.

- Oil & Gas Refineries – for process tube bundle and pipeline cleaning.

- Distilleries & Breweries – for heat recovery and evaporation plant tube cleaning.

- Textile & Engineering Industries – for heat exchanger, evaporator, and process pipe cleaning during annual overhauls.

- Engineering Shutdown Maintenance Contractors – for tube bundle, heat exchanger, evaporator, condenser tube, and industrial pipeline cleaning.

PressureJet hydro jetting machines ensure efficient scale removal, improved heat transfer, and reduced downtime, enhancing the performance of critical heat exchange equipment while significantly reducing maintenance costs — thanks to innovative design, high precision engineering, and superior manufacturing quality.

- Ensures precise pressure cut-off for maximum pump safety.

- Heavy-duty FOV-30 Safety Valve designed for high-pressure systems.

- Compact, reliable and easy to install on pump outlets.

- Suitable for hydro jetting, descaling, industrial cleaning & safety compliance.

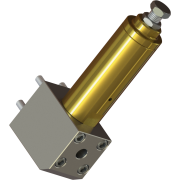

- Provides superior pressure control for extra heavy-duty pump operations

- Rugged T-70 PRV construction ensures durability in extreme conditions.

- Easy installation and minimal service requirements.

- Perfect for hydro jetting, Fin Cleaning, Pipe and tube cleaning, & industrial cleaning industries.

- DG-30 Dump Gun with full SS body engineered for ultra-high pressure operations.

- Suitable for applications up to 1500 bar with assured durability and safety.

- Covered by shockproof semi-housing and ergonomic trigger for operator comfort.

- Perfect for hydro blasting, surface preparation, tank cleaning & industrial jetting.

- Heavy-duty safety suit designed for operators working with ultra-high pressure water jetting

- Made from multi-layer ballistic fabric for cut, puncture and water-jet resistance.

- Ergonomically designed for mobility and comfort during extended operations.

- Includes jacket, trousers, helmet visor and protective boots for full-body safety.

- Flexible Lance Safety Stop prevents hose whip accidents during high-pressure water jetting.

- Designed for operator safety when using flexible lances in heat exchanger and pipe cleaning.

- Constructed with robust stainless steel and safety locking mechanism for reliability.

- Easy to attach and ensures controlled lance movement under ultra-high pressure.

- Rupture disk provides instant pressure relief to protect pumps and operators from overpressure.

- Designed for precise burst pressure ratings to safeguard ultra-high pressure systems.

- Compact design allows easy integration into high-pressure jetting systems.

- Essential safety device for hydro blasting, heat exchanger & industrial cleaning systems.

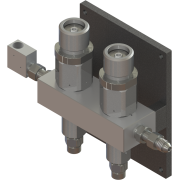

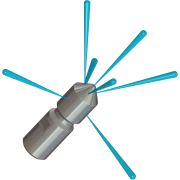

- High-pressure flow divider valve for hydro jetting, blasting, and cleaning after pickling operations.

- Provides equal flow distribution to multiple guns, lances, or rotary nozzles from one pump line.

- Engineered from corrosion-resistant stainless steel for durability in chemical and high-pressure environments.

- Ideal for hydro blasting, chemical cleaning, pickling line cleaning, and industrial maintenance.

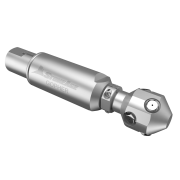

- Flexible high-pressure lance designed for efficient cleaning of curved and long heat exchanger tubes.

- Rated for 1400 BAR working pressure with reinforced dual-braided steel for maximum durability.

- Compatible with rotary nozzles, quick couplers, and foot-operated safety valves for operator convenience.

- Available in custom lengths and sizes to match specific hydro jetting requirements.

- Interchangeable heads allow the tool to be used with any type of pump

- Multiple head options to allow for flush mounted nozzles, extension arms, plugs and pulling rings

- Simple nozzle changes allow operators to configure for multiple cleaning applications

- Easy to pair with AutoBox ABX-500 for hands-free pipe or tank cleaning

- High flow range aids in removing thick, tough deposits

- Controlled rotation for longer jet dwell times help remove hard material

- Multiple jetting options allows for fine tuning heads to optimize cleaning

- Optional centering devices available to optimize standoff distance

- Different jetting configurations allow for more or less pull and forward hitting power

- Speed controlled rotary tools provide complete internal cleaning coverage and optimum jet delivery

- Maximize cleaning by choosing slower speeds for hard to clean or plugged pipes and faster speeds for polishing easy to clean pipes with a single tool

- Pair with the ABX-500 for hands-free pipe cleaning

- 5X longer runtime between maintenance intervals

- Redesigned braking system maintains consistent speed over longer duration

- Body shape allows for more effective navigation of bends and elbows and minimizes tool hangup during removal

- Designed to easily pair with the AutoBox ABX-500 hose tractor for hands-free pipe cleaning

- Navigates pipes with bends as small as 2 inches (51 mm) in diameter

- Drilled heads improve reliability while delivering the same power and life

- Three pre-drilled heads available that cover all required pressure and flow configurations

- Engineered for long-term use with low-cost head replacements and no bearings, seals, or lubricants to maintain

- Ideal for unplugging, cleaning and polishing tubes, such as those found in heat exchangers and industrial tube bundles

- Stainless steel construction for extreme durability and longevity

- Effectively remove thin, hard scale, carbons, coke, and polymers

- Polisher, Unplugger, and Universal heads available

- Head rotation provides complete internal coverage while speed control delivers optimum jet dwell time

- Easily re-jet the Gopher for more pulling force or forward hitting power depending on the needs of the job

- External port plug allows for fluid refill without tool disassembly

- Polisher, Unplugger, and Universal heads available

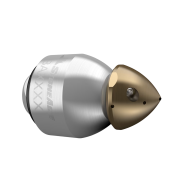

- Pressurejet Tube cleaning nozzles can be used with flexible lance or Rigid Lance.

- Nozzles made from hardened stainless steel.

- Tube cleaning nozzles Available in 8 sizes, 13 Jet pattern and 10 flow rating

- Custom jet patterns and flows available on request.