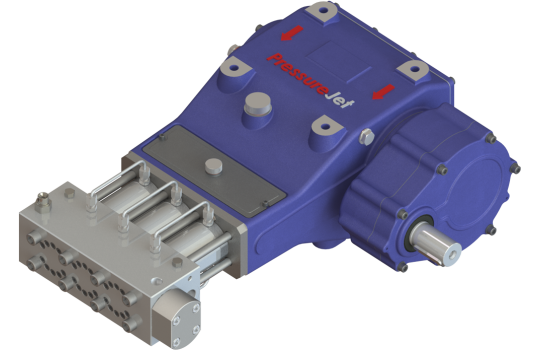

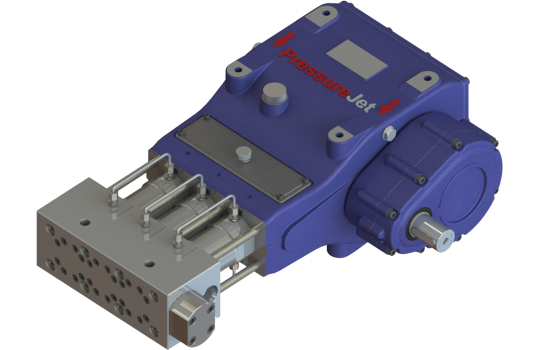

PressureJet – India’s Most Preferred High Pressure Reciprocating Triplex Plunger Pump Brand

PressureJet High Pressure Plunger Pumps are high precision rotating hydraulic systems. Operating at around 600 SPM (strokes per minute), the crankshaft motion is converted into reciprocating action via the connecting rod, crosshead, and plunger, generating hydraulic pressures up to 1400 Bar; with 10 reciprocation cycles per second per plunger.

Engineered for Excellence: With GD&T tolerances up to 8 microns and precision machining on Mazak 9-axis mill-turn, Mazak HMC, Kafo double-column VMC, and BFW VMC machines, PressureJet pumps deliver long-term reliability, minimal temperature rise during continuous operation, superior mechanical and volumetric efficiency, and significantly lower wear and tear — setting the benchmark for industrial performance.

Despite their export-grade quality, PressureJet High Pressure Pumps are competitively priced for Indian buyers, supporting high-performance operations while serving the nation.

Consult PressureJet Today to experience industry-leading precision, reliability, and efficiency in high-pressure triplex plunger pumps — engineered for the most demanding industrial applications.

PressureJet Quality Claims:

- Lowest Noise Level in Segment – Quiet, smooth operation.

- Vibration Level – Minimal, as per ISO 10816-6, ensuring stable operation.

- Controlled Temperature Rise – Maximum 50°C during continuous operation.

- Mechanical Efficiency – Above 85%, optimal power transmission.

- Volumetric Efficiency – Above 85%, precise fluid delivery per stroke.

- Proven Reliability – Tested for minimum 200 hours continuous operation at rated pressure.

Precision Manufacturing and Testing:

- Over 90% in-house production on advanced CNC machines.

- GD&T tolerances up to 8 microns for ultimate dimensional accuracy.

- Rigorous alignment, pressure, and operational testing to meet the highest industrial standards.

Applications of PressureJet High-Pressure Triplex Plunger Pumps

- Hot Steel Descaling Systems – Efficient scale removal from billets, blooms, slabs, pipes, TMT bars, and profiles.

- UHP Fire Fighting Pumps – Ultra High Pressure fire suppression for industrial and mobile firefighting units.

- Industrial High-Pressure Cleaners – Heavy-duty cleaning of process equipment, vessels, and pipelines.

- High-Pressure Hydro Test Pump Systems – Hydrostatic testing of cylinders, boilers, tubes, pipes, valves, and castings.

- High-Pressure Water Mist Fire Suppression Systems – Safe and efficient fire suppression in industrial and commercial setups.

- Metal Powder Water Atomization Pumps – Precision atomization of molten metals for ferrous, non-ferrous, and alloy powders.

- Water Sand Blasting Machines – Surface preparation, paint removal, rust removal, and industrial cleaning applications.

- Hydro Jetting Machines – Cleaning of heat exchanger tubes, pipes, and industrial pipelines.

- Hydro Blasting Machines – High-pressure cleaning for reactors, vessels, and industrial surfaces.

- Sewer Jetting Pumps – Municipal and industrial sewer and drainage cleaning.

- Tank and Reactor Cleaning Systems – Cleaning of chemical reactors, storage tanks, and process vessels.

- ACC Fin Cleaning Pumps – Cleaning of air-cooled condenser fins, heat exchangers, and cooling towers in cement, power, and process industries.

- Ensures maximum safety by releasing excess pressure automatically.

- Compact S-20 Safety Valve built for reliability and long life.

- Quick response mechanism for over-pressure protection.

- Widely used in hydro jetting, descaling, tube cleaning & industrial cleaning.

- Ensures accurate pressure regulation for safe pump operation.

- Built with rugged design for long-lasting durability.

- Easy to install and low-maintenance accessory.

- Ideal for High Pressure Industry.

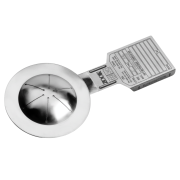

- Rupture disk provides instant pressure relief to protect pumps and operators from overpressure.

- Designed for precise burst pressure ratings to safeguard ultra-high pressure systems.

- Compact design allows easy integration into high-pressure jetting systems.

- Essential safety device for hydro blasting, heat exchanger & industrial cleaning systems.

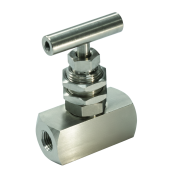

- Precision flow control valve designed for accurate pressure and flow regulation up to 1400 BAR.

- Tapered stem design provides smooth throttling and leak-free shutoff under high pressure.

- Available in various connection sizes and pressure ratings for flexible system integration.

- Ideal for hydro jetting, descaling, and high-pressure process water applications.

- High-accuracy pressure gauge for continuous monitoring up to 1500 BAR.

- Built with stainless steel casing and glycerin-filled design to resist vibration and corrosion.

- Provides real-time, precise readings for pump performance and safety assurance.

- Available in bottom or back mount designs with multiple dial sizes for easy integration.