Ensure Leak-Free Performance with PressureJet Hydro Test Pumps

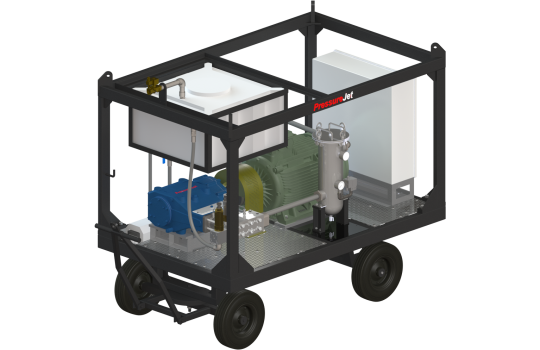

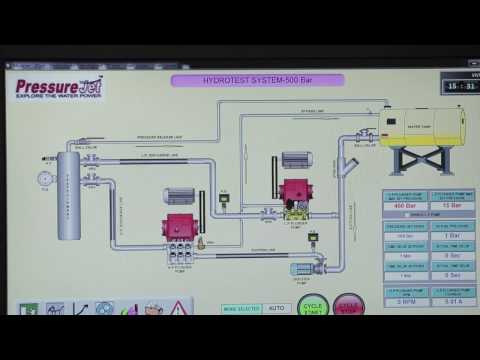

PressureJet High Pressure Hydro Test Pump and Systems deliver accurate, safe, and reliable hydrostatic testing for tubes, seamless pipes, cross-country pipelines, composite cylinders, pressure vessels, boilers, valves, and other critical components. Designed for low-volume testing (hundreds of liters) at high pressures up to 1400 bar and high-volume testing (hundreds of thousands of liters) at low to medium pressures up to 500 bar, these systems ensure precise leak detection and protect component integrity with advanced safety relief and control mechanisms.

With flow ranges from 8 LPM to 485 LPM, pressures from 70 bar (1000 PSI) to 1400 bar (20,000 PSI), and power ratings from 30 HP to 180 HP, pumps are available in electric motor-driven variants for frequent on-site use and diesel engine-driven models for remote locations, oilfields, and industrial plants, offering flexible, high-performance solutions across all industrial hydrostatic testing requirements.

Applications of PressureJet Hydro Test Pump Systems

PressureJet hydro test pumps are widely used across industries for rigorous pressure testing and leak detection:

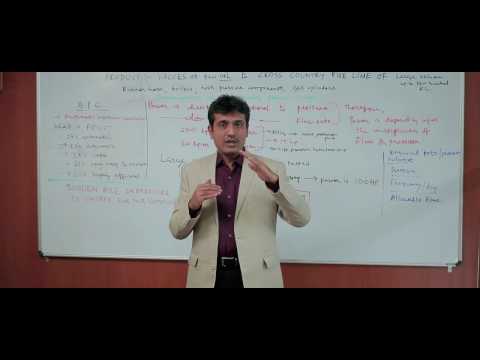

- Pipes and Tubes: Hydrostatic testing of cross-country pipelines, heat exchanger tubes, and industrial tubing

- Cylinders & Vessels: Hydro testing of pressure vessels, boilers, and composite cylinders

- Valves & Castings: Checking valves, flanges, and critical cast components for leaks

- Industrial Components: Pumps, compressors, and fabricated assemblies

- Oil & Gas: Hydro testing of pipelines, manifolds, and pressure vessels

- Construction & Infrastructure: Testing pipelines, water supply systems, and industrial installations

Leverage PressureJet’s mastery in high-pressure pump selection for cross-country pipelines.

Consult us for uniquely designed testing pump combinations — optimized for maximum ROI, superior performance, and unmatched quality.

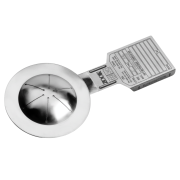

- Ensures maximum safety by releasing excess pressure automatically.

- Compact S-20 Safety Valve built for reliability and long life.

- Quick response mechanism for over-pressure protection.

- Widely used in hydro jetting, descaling, tube cleaning & industrial cleaning.

- Delivers precise pressure regulation for large high-flow pump systems

- Heavy-duty T-60 PRV designed for maximum industrial performance.

- Simple to install with low maintenance requirements

- Perfect for hydro test, descaling, tube cleaning, sewer jetting & industrial cleaning applications.

- Rupture disk provides instant pressure relief to protect pumps and operators from overpressure.

- Designed for precise burst pressure ratings to safeguard ultra-high pressure systems.

- Compact design allows easy integration into high-pressure jetting systems.

- Essential safety device for hydro blasting, heat exchanger & industrial cleaning systems.

- Full-bore high-pressure ball valve ensures smooth, unrestricted flow with minimal pressure loss.

- Handles pressures up to 1400 BAR with precision-sealed ball and seat mechanism.

- Suitable for hydro testing and industrial fluid systems.

- Ideal for high pressure cleaning, and industrial process systems.

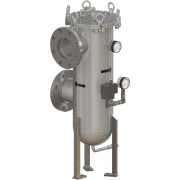

- 80–100 micron precision sand filtration for fine particle and scale removal.

- Extends pump, nozzle, and valve life by preventing contamination and abrasion.

- Available in MS, SS, and FRP construction with optional backwash system.

- Ensures stable pressure and consistent filtration in descaling operations.

- High-accuracy pressure gauge for continuous monitoring up to 1500 BAR.

- Built with stainless steel casing and glycerin-filled design to resist vibration and corrosion.

- Provides real-time, precise readings for pump performance and safety assurance.

- Available in bottom or back mount designs with multiple dial sizes for easy integration.