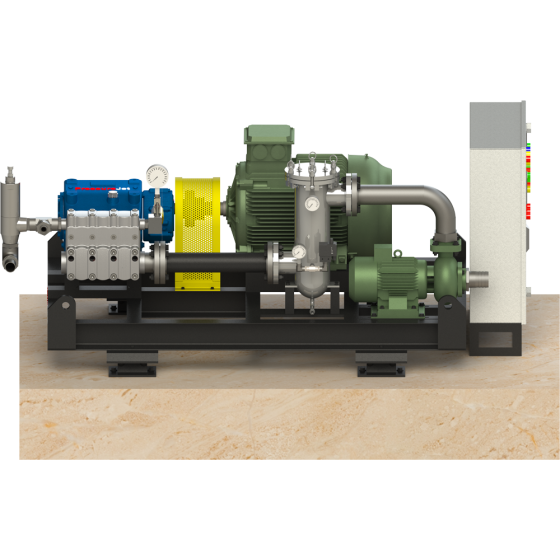

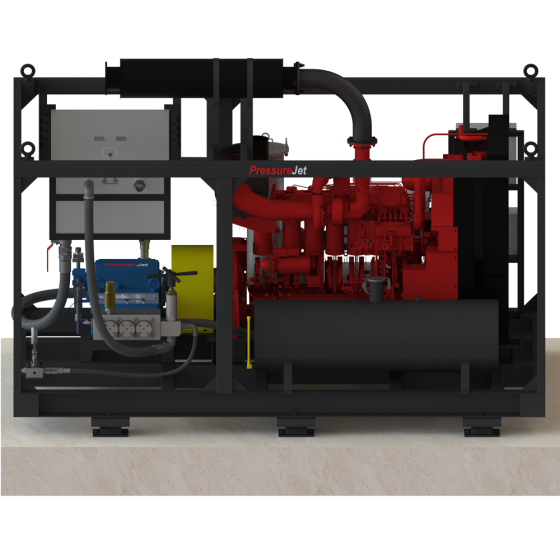

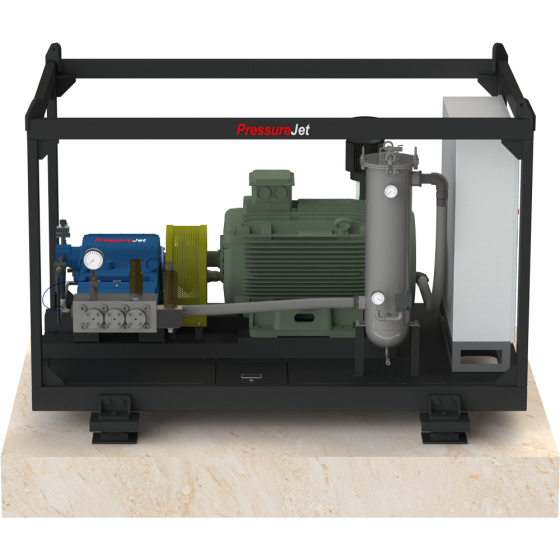

High Pressure Hydrostatic Pressure Test Unit

High pressure hydrostatic pressure test units are common procedure used to check fluid pressure vessel, such as, cylinders, boiler, tubes pipe, valves, castings, components etc.. High pressure hydrostatic pressure test unit is also a common testing procedure to verify pressure vessels do not leak or have manufacturing flaws. Hydrostatic hydro test pumps & equipment is important for pressure vessels in the interest of device safety, and durability under operating pressure.

The pressure vessel to be tested is located within a sealed vessel. The sealed vessel is filled with a in compressible fluid, typically water or oil. The pressure test vessel is then subjected to a known internal pressure for a known duration. The known internal pressure is normally a significant percent greater than the maximum operating pressure of the device (typically 150%). The applied pressure causes the test vessel to expand, instrumentation, which is already in place, are then read to determine the total and permanent expansion that the test chamber (external) undergoes. A physical and visual inspection then follows the hydrostatic pressure test to determine that the device being tested has not been damaged or permanently distorted due to the test pressure.