Get More Than 90 percent descaling Efficiency with Unique PressureJet Descalers

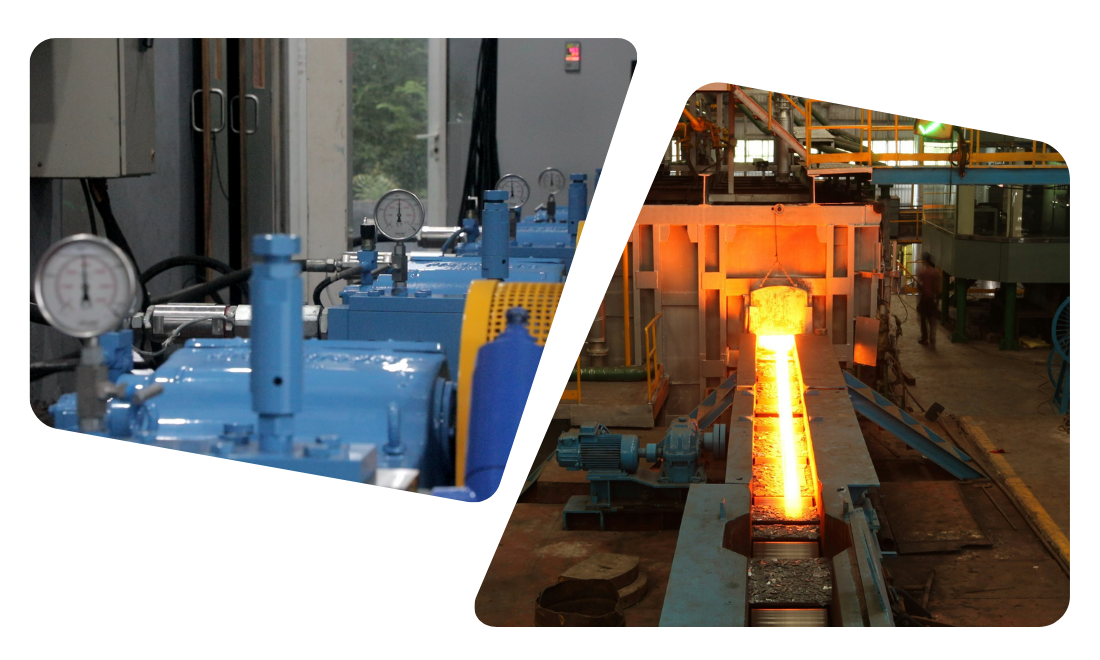

PressureJet Hot Steel Descaling Systems are engineered to deliver exceptional descaling performance, achieving over 90% scale removal efficiency thanks to our unique header design and optimized impact force calculations tailored for different materials and furnace types. Each descaler is precision-engineered to generate high-pressure water jets with razor-sharp impact, producing mechanical force strong enough to efficiently remove oxide layers from billets, blooms, slabs, pipes, TMT bars, ingots, profiles, and wire rods.

During the re-heating of metal in furnaces, surface scale forms due to high temperatures up to 1250°C, oxygen, and process gases. PressureJet descalers remove this scale without damaging the steel, while angled high-pressure jets wash away the loosened oxide, ensuring defect-free surfaces and minimal material loss.

PressureJet Hot Steel Descaling Systems eliminate manual scale handling, ensuring safer operations while delivering superior surface quality for end steel products. By efficiently removing scale, our systems reduce wear on rollers and extend their operational life, resulting in higher productivity and lower maintenance costs.

Primary & Secondary Descaling System Solutions

PressureJet offers comprehensive descaling solutions tailored to the needs of modern steel production:

- Primary Descaling Systems: Remove the bulk of scale immediately after furnace heating, ensuring uniform impact across billets, blooms, slabs, and ingots.

- Secondary Descaling Systems: Target remaining scale or hard-to-clean areas post-rolling, perfect for edges, profiles, TMT bars, and complex geometries, ensuring defect-free steel.

Upgrade Your Steel Production Today

Achieve over 90% scaling efficiency, maximize surface quality, reduce maintenance, and boost productivity with PressureJet Hot Steel Hydro Mechanical Descaling Systems.

Consult PressureJet Experts for Descaling Solutions. We provide tailored solutions for Mild Steel, High Carbon Steel, Alloy Steel, Bearing Steel, Tool Steel, and Stainless Steel hot rolling mills.

- PressureJet Telematic IoT System for real-time monitoring of pump performance and safety.

- Tracks pressure, flow, temperature and vibration data with cloud-based logging.

- Enables predictive maintenance and reduces downtime with smart alerts.

- Remote access via web dashboard and mobile app for 24/7 equipment visibility.

- Descaling nozzle engineered for efficient removal of scale, rust, and surface deposits using high-pressure water.

- Designed with precision orifice geometry to deliver uniform impact and optimized cleaning performance.

- Available in multiple jet configurations (0°, 15°, 25°, 40°) for targeted descaling of pipes, billets, and rolls.

- Manufactured from hardened stainless steel or tungsten carbide for maximum wear resistance and long life.

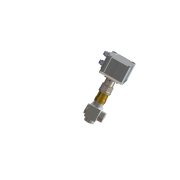

- Pneumatically controlled VRPP ensures smooth and precise water pressure regulation for industrial descaling systems.

- Equipped with 3/2 solenoid valve and FRL unit, ensuring stable air flow and responsive pressure control.

- Designed for high flow and pressure ranges (up to 450 LPM @ 310 BAR) with excellent repeatability and safety.

- Built using high-strength stainless steel and brass components for long life under demanding conditions.

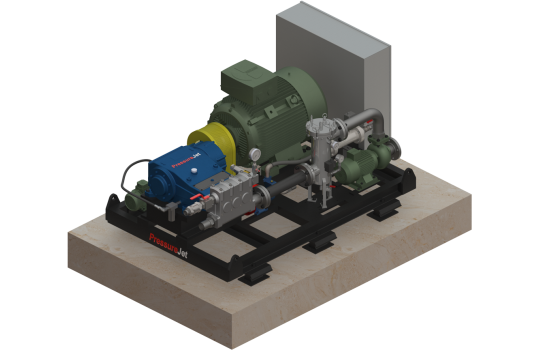

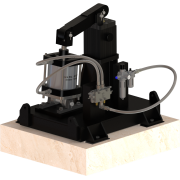

- Heavy-duty model developed for high-flow industrial descaling and large rolling mill applications.

- Incorporates a reinforced pneumatic actuator for fast and stable ON–OFF response under full load.

- Built for continuous operation at 350 BAR with precision-machined internal geometry.

- Ideal for slab descaling, bloom descaling, and wide-strip rolling mill systems.

- Infrared-based hot metal detector for accurate detection of billets, bars, or slabs in descaling lines.

- Triggers automatic ON–OFF valve actuation in synchronization with the rolling process.

- Designed to withstand high ambient temperatures, dust, and vibration in steel mill environments.

- Ideal for steel mill descaling automation, hot rolling lines, and billet/bloom position sensing.

- Allows precise speed and pressure control for energy-efficient operation.

- Integrated with IoT and telemetry compatibility for real-time monitoring.

- Suitable for applications requiring variable flow and smooth start/stop.

- Optimizes power consumption and pump longevity.

- Reduces pressure fluctuations and vibration caused by reciprocating plunger pumps.

- Enhances system stability, nozzle performance, and pump life by ensuring steady discharge flow.

- Available in carbon steel and stainless steel construction with replaceable bladder options.

- Suitable for hydro jetting, hydro blasting, pipe cleaning, and high-pressure process systems.

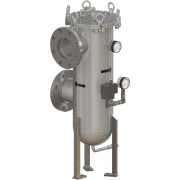

- 80–100 micron precision sand filtration for fine particle and scale removal.

- Extends pump, nozzle, and valve life by preventing contamination and abrasion.

- Available in MS, SS, and FRP construction with optional backwash system.

- Ensures stable pressure and consistent filtration in descaling operations.

- High-accuracy pressure gauge for continuous monitoring up to 1500 BAR.

- Built with stainless steel casing and glycerin-filled design to resist vibration and corrosion.

- Provides real-time, precise readings for pump performance and safety assurance.

- Available in bottom or back mount designs with multiple dial sizes for easy integration.