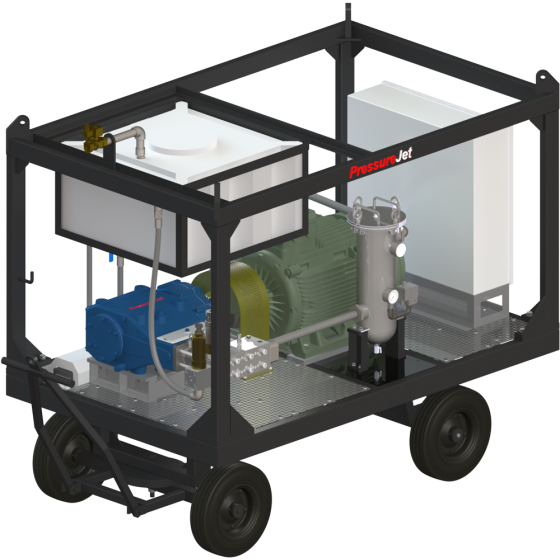

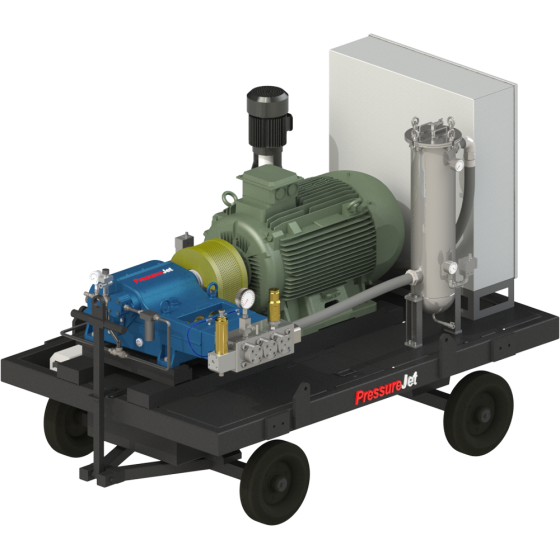

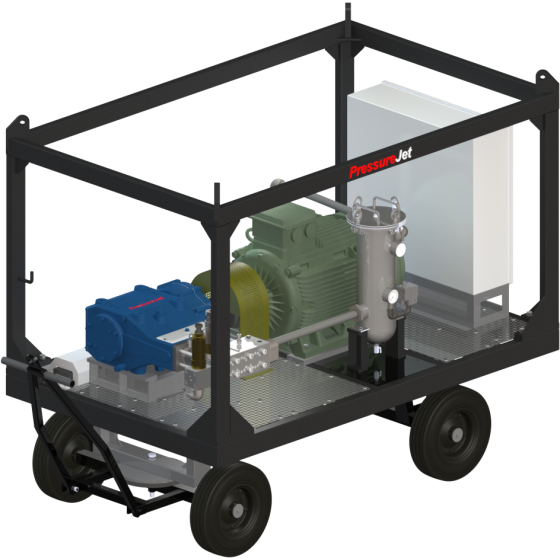

High Pressure Hydro Blaster Machines

High-pressure hydro blasting, also known as water jetting or water blasting, involves the use of high-pressure water as a precise and powerful tool for surface cleaning and preparation. Unlike traditional abrasive methods, hydro blasting relies solely on the kinetic energy of water to remove contaminants such as dirt, rust, corrosion, paint, or chemical residues.

Since no abrasive material is used, dust generation and waste disposal issues associated with abrasive blasting are completely eliminated—making it an environmentally safe and clean process.

Surface Condition After Hydro Blasting

Flash Rust Formation

During large-scale hydro blasting operations, flash rust may appear on freshly cleaned metal surfaces before coating or painting. The degree of flash rust depends on factors such as ambient humidity, temperature, and exposure duration.

Classification of Flash Rust:

-

Light Flash Rust: Small patches or light tan-brown discoloration appear on the surface. Brushing does not leave any marks.

-

Medium Flash Rust: A thin, uniform, or patchy tan-brown layer develops. Light brushing may leave faint marks.

-

Heavy Flash Rust: A dense, dark brown layer fully covers the steel surface and easily marks when touched or brushed.

Temperature Impact

High Pressure Hydro Blaster Machines increase the surface temperature of steel during operation, which accelerates the drying process and minimizes flash rust formation. This helps achieve a cleaner, ready-to-coat surface in a shorter time.

Removal of Foreign Contaminants

High-pressure water efficiently removes oil, grease, salt deposits, and loose corrosion products from the substrate.

Discoloration remaining after cleaning—such as grey, brown, or black shades on pitted steel—consists mainly of ferric oxide, a stable and non-contaminating material that poses no risk to subsequent coating adhesion.

Surface Profile Characteristics

High Pressure Hydro Blaster Machines do not inherently create a surface profile. Any visible profile after cleaning typically results from prior surface corrosion, mechanical preparation, or existing roughness. On weak or previously corroded steel, a minor degree of surface erosion may occur but remains within safe limits.

Advantages of High Pressure Hydro Blaster Machines

-

Environmentally friendly process – no chemicals or abrasives required

-

Effective removal of oil, grease, salts, and tough deposits

-

Minimized flash rusting through accelerated drying

-

Ideal for sensitive or pre-prepared steel surfaces

-

Clean and residue-free finish ready for coating or inspection