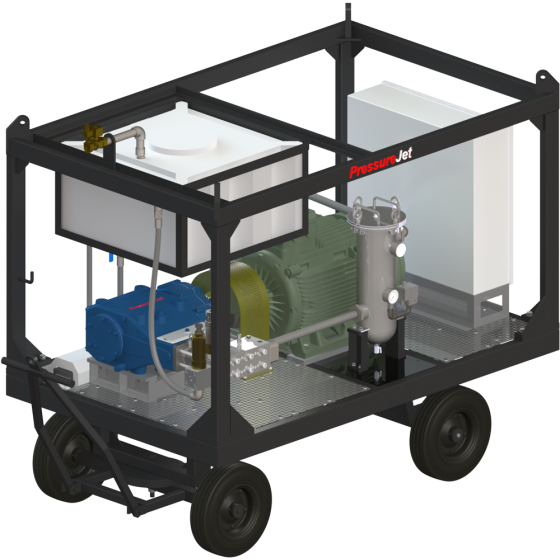

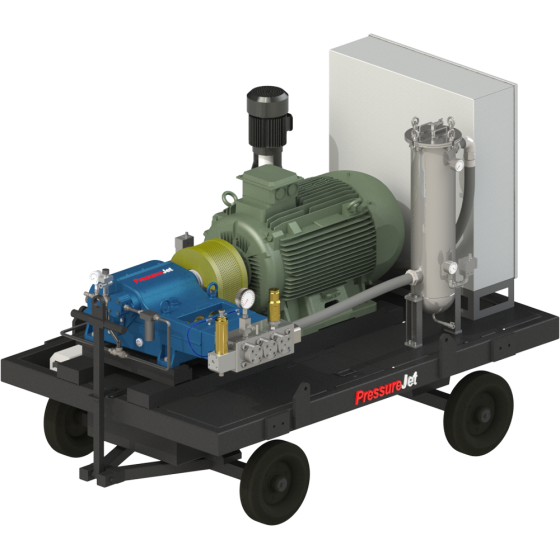

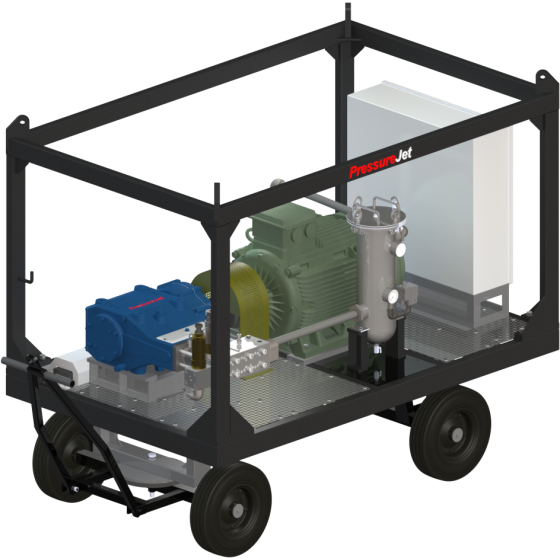

High Pressure Hydro Blaster

High-pressure hydro blasting, water jetting, or water blasting refers to the use of high-pressure water as a tool for surface preparation and cleaning. Unlike abrasive-based methods, hydroblasting relies entirely on the force and energy of water to remove dirt, corrosion, or other deposits. Since no abrasive is used, issues related to dust pollution and spent abrasive disposal are completely eliminated.

Surface Condition After Hydroblasting

Flash Rust:

During large-scale water blasting, flash rust may develop, affecting the original surface finish before painting or coating. The extent of flash rust depends on humidity, temperature, and exposure time.

Degrees of Flash Rust:

-

Light flash rust: Small patches or light tan-brown discoloration appear on the steel surface. Objects brushed against it will not leave marks.

-

Medium flash rust: A thin, evenly or patchily distributed layer of tan-brown rust covers the steel. Objects may leave light marks.

-

Heavy flash rust: A dense, dark tan-brown rust layer fully covers the steel, easily marking objects that contact the surface.

Temperature Effects:

High-pressure hydro blasters increase the steel surface temperature during operation. This accelerates drying and helps reduce the formation of flash rust, ensuring a cleaner surface in less time.

Removal of Foreign Elements:

High-pressure water effectively removes oil, grease, and salt deposits from surfaces. Discoloration from corroded or pitted steel after hydroblasting (grey, brown, or black) consists mainly of ferric oxide, an inert material. This adherent film is not harmful and does not pose contamination concerns.

Surface Profile

High-pressure hydro blasters do not inherently create a surface profile. Any exposed surface profile is usually the result of prior preparation or corrosion, and weak steel may experience minimal erosion.

Advantages of High-Pressure Hydro Blaster:

-

Environmentally safe, no chemical or abrasive residue

-

Efficient removal of oil, grease, salt, and deposits

-

Reduced flash rust due to faster drying

-

Suitable for sensitive or pre-prepared steel surfaces