Heat Exchanger Tube Cleaning Equipment

You’re at the right place for advanced tube and pipe cleaning solutions. PressureJet offers ultra-high-pressure water jetting equipment for:

-

Heat exchanger tube cleaning

-

Condenser tube cleaning

-

Evaporator tube cleaning

-

Various industrial pipe cleaning applications

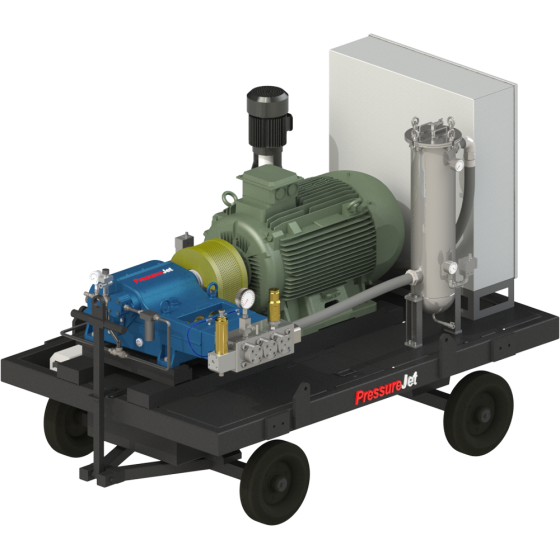

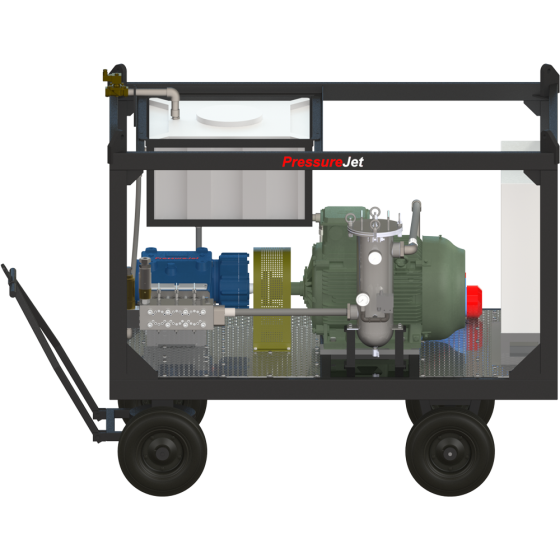

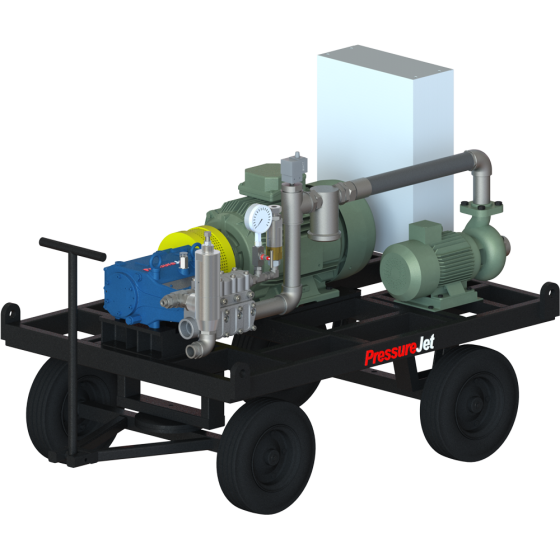

Our high-pressure hydrojetting systems feature reciprocating plunger pumps with pressures ranging from 140 bar (2,000 psi) up to 1400 bar (20,000 psi) and flow rates up to 700 LPM, delivering safe, fast, and efficient cleaning.

We manufacture Electric Motor Driven as well as Diesel Engine Driven complete systems with compatible tube cleaning accessories including:

-

Foot Operated Valves

-

Flexible Lances

-

Rigid Lances

-

Conventional Tube Cleaning Nozzles

-

Rotating Tube Cleaning Nozzles

Our specially designed nozzles cover tube IDs from 12 mm to 76 mm and larger pipe IDs from 3 to 16 inches, ensuring effective cleaning for a wide range of applications.

Contact PressureJet to select the right system for your requirement.

Advantages of High-Pressure Hydrojetting

Using water jetting over conventional methods like chemical or brush cleaning provides numerous benefits:

-

Safe for all tube materials – From brass to titanium

-

Prevents corrosion & extends tube life – Removes corrosive deposits and tube pits

-

Cleans any tube size – Straight or U-tube, any diameter or length

-

Maximizes efficiency – Removes fine silt and organic debris that mechanical cleaning often misses

-

Removes all foreign scale deposits

-

Environmentally friendly – No chemical discharge or hazardous waste

-

Custom-designed nozzles – Provide 360° inner diameter cleaning without streaks

-

Multiple lance systems – Up to 8 operators for fast cleaning of large condensers

-

Radiological waste minimization – Positive shut-off pressure control systems

-

Cost-effective – Restores performance quickly and extends refouling intervals

Tube and pipe cleaning is essential for maintaining fouled tubes. While chemical cleaning may still be required for certain deposits, high-pressure hydrojetting provides a residue-free, fast, and safe alternative, reducing chemical use and disposal costs.

Applications

PressureJet tube cleaning pumps are widely used across industries such as:

-

Textiles

-

Pharmaceuticals

-

Steel & Metallurgy

-

Chemical Processing

-

Refineries

-

Power Plants

-

And many more

Our systems have been deployed across India and internationally in countries including South Africa, Malaysia, Philippines, Thailand, Korea, Iran, Saudi Arabia, Brazil, Mexico, Israel, Indonesia, and more.

Pump Options & Features

-

Available with Diesel Engine or Electric Motor

-

Modern high-pressure waterjet pumps deliver a smooth, residue-free surface

-

Compatible with a wide range of tube cleaning accessories

-

No costly chemical cleanup or hazardous waste disposal required

? PressureJet High-Pressure Tube Cleaning Systems – Efficient, safe, and environmentally friendly solutions for maximum heat exchanger, condenser, and evaporator performance.